Polymer Training and Innovation Centre

About the Polymer Training Innovation Centre

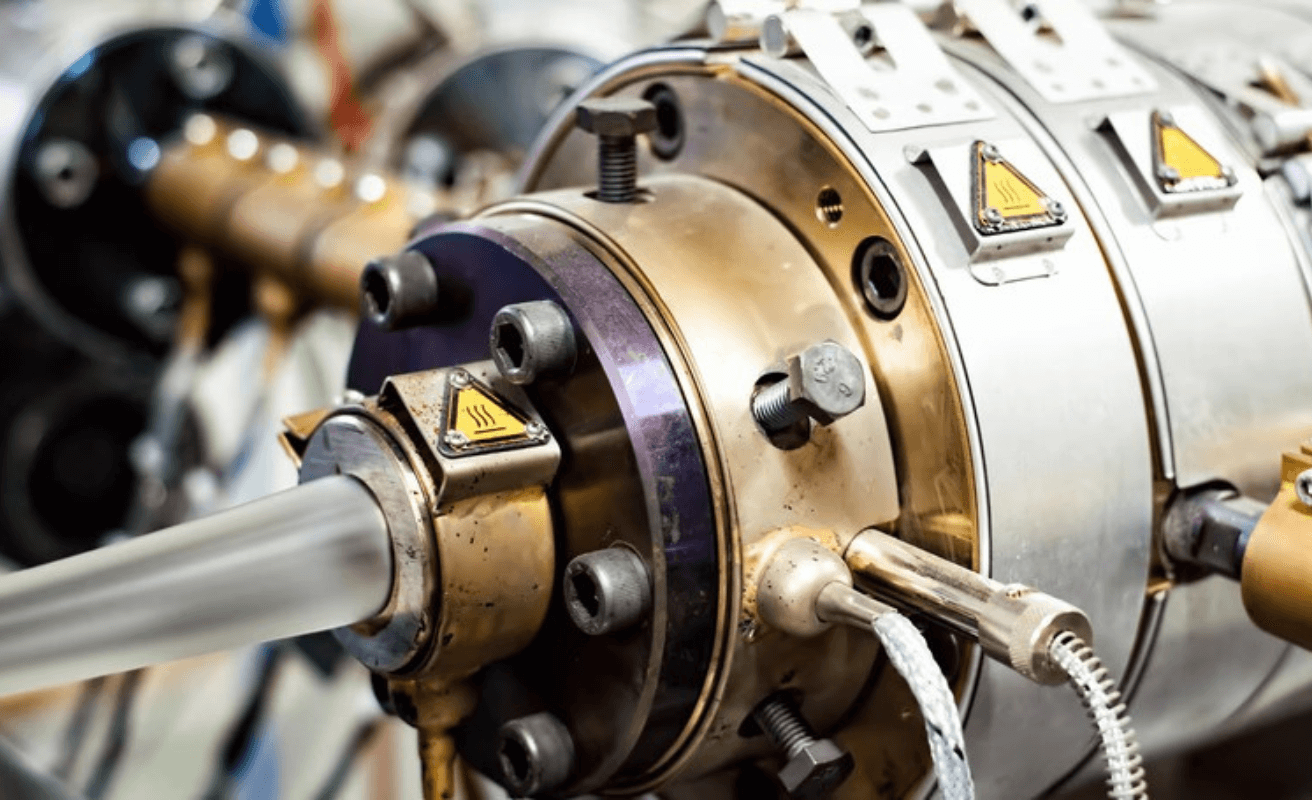

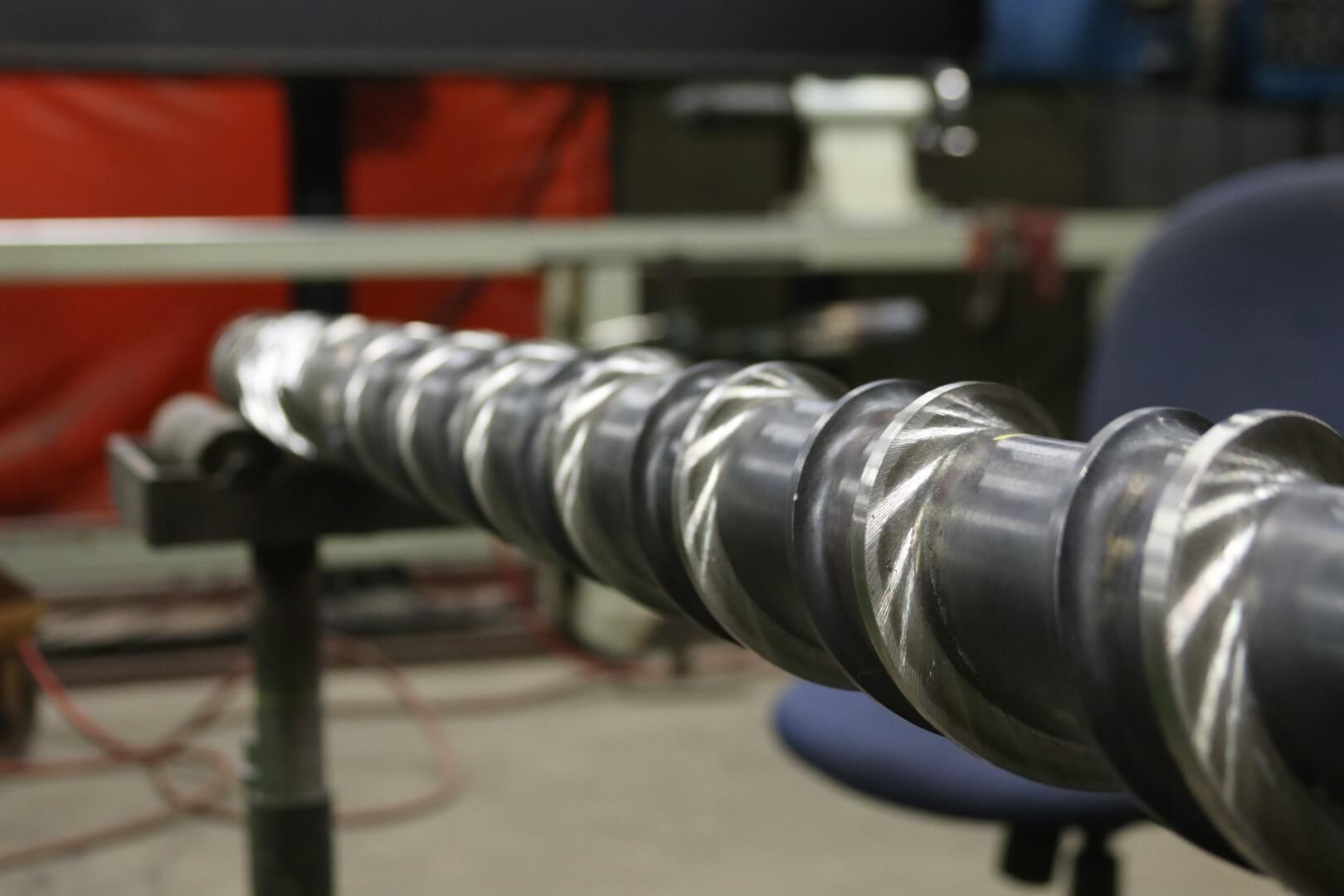

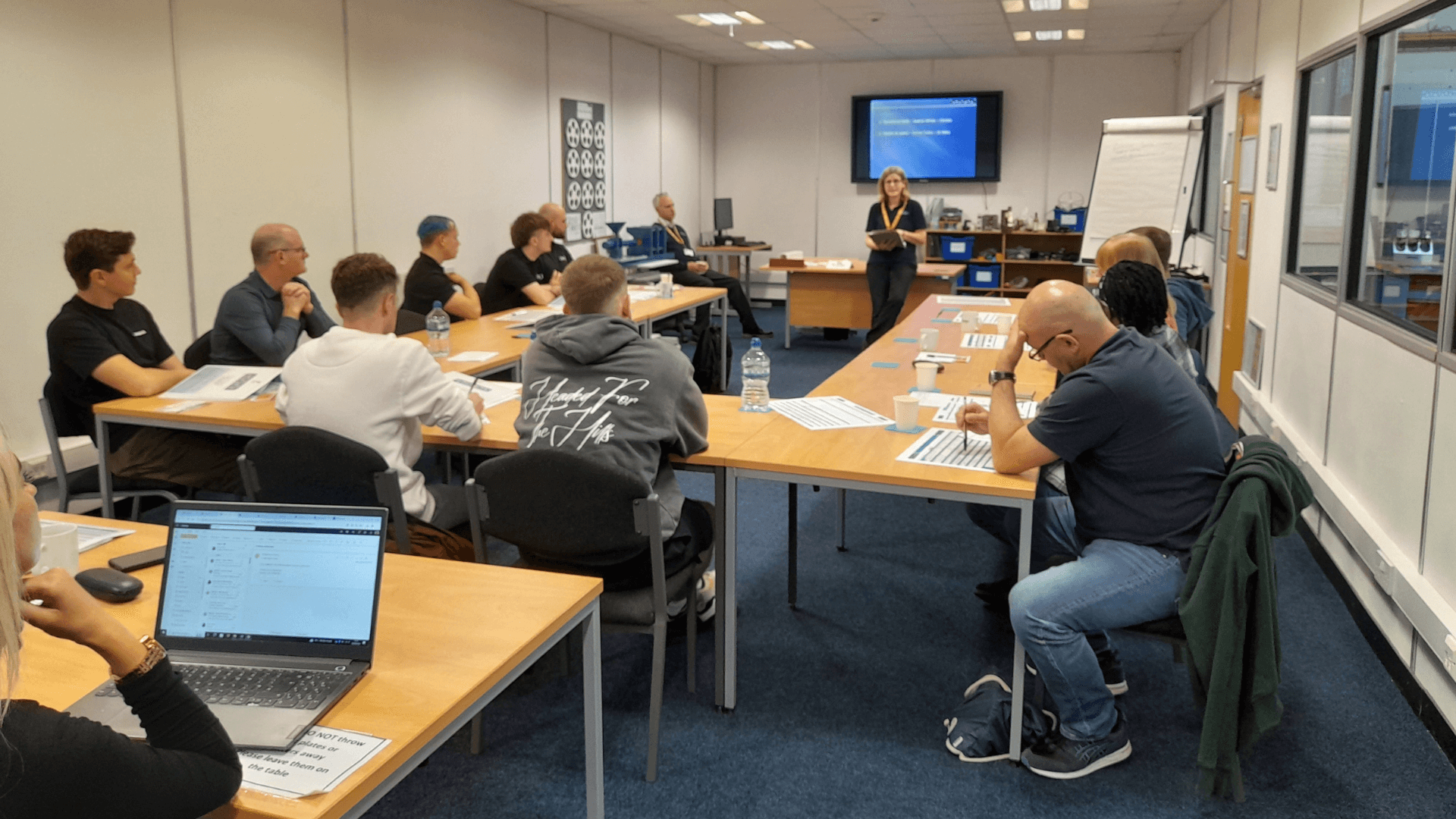

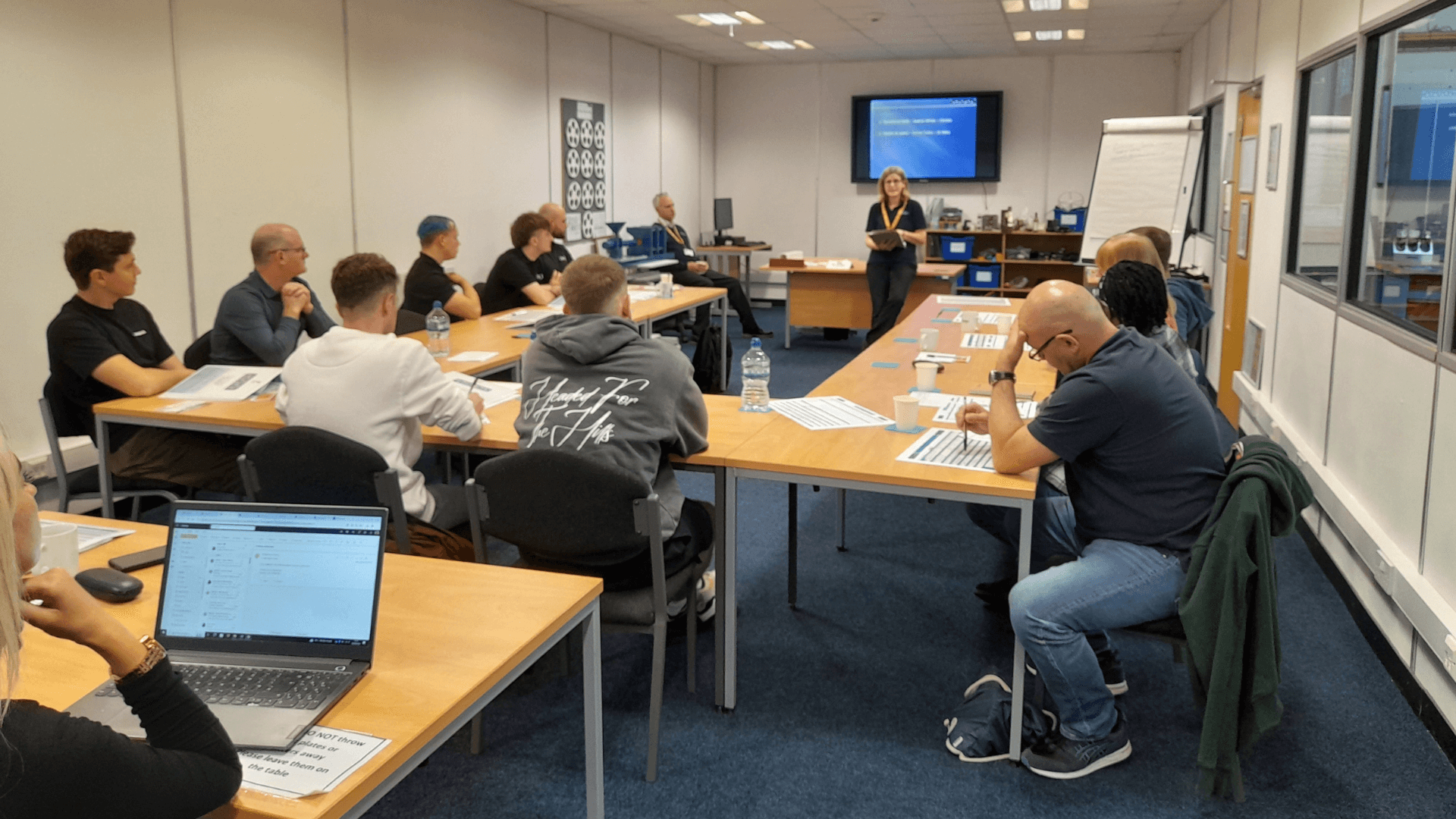

The college’s Polymer Training and Innovation Centre offers specialist training and consultancy in:

- Injection moulding

- Blow moulding

- Extrusion

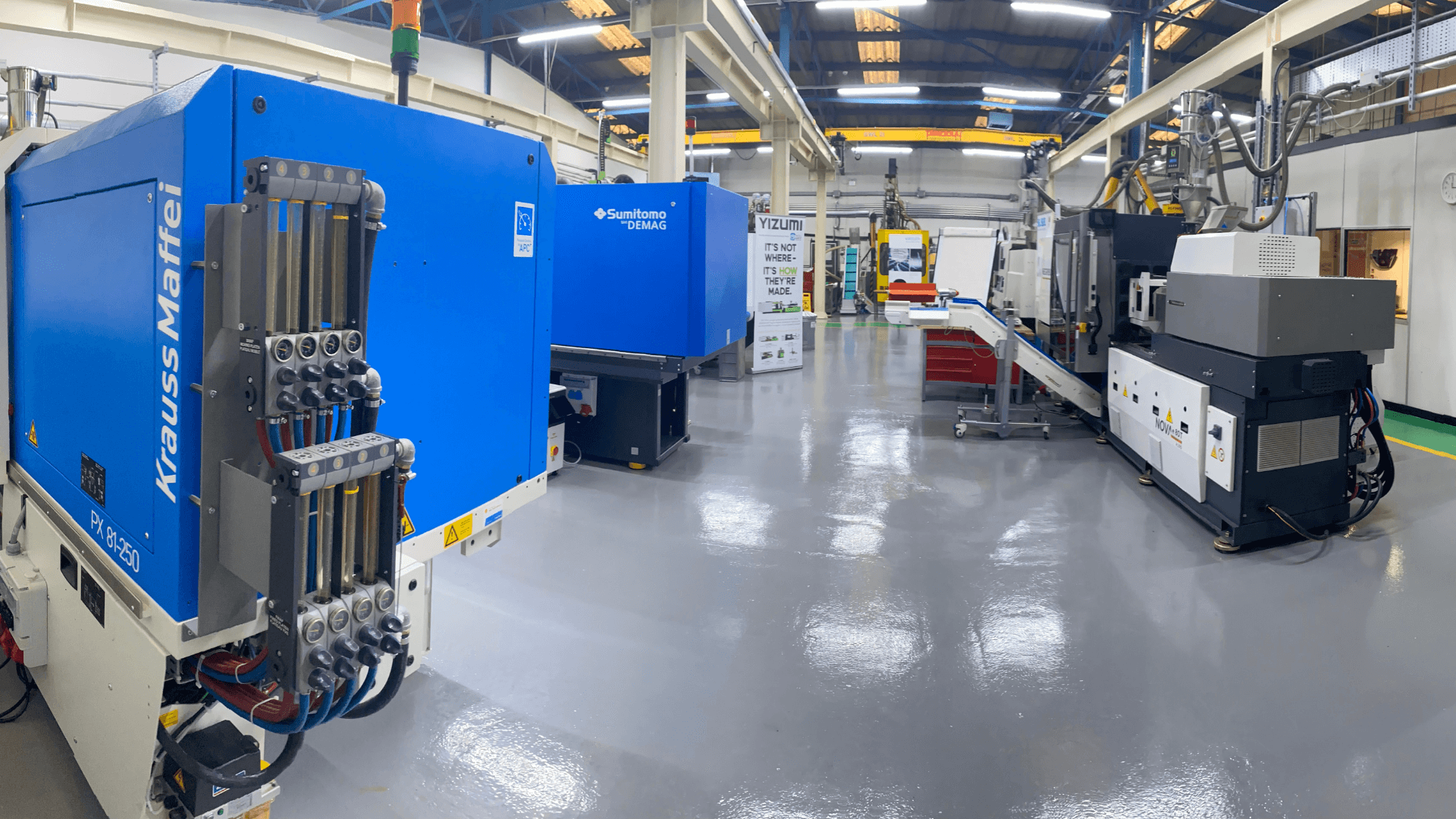

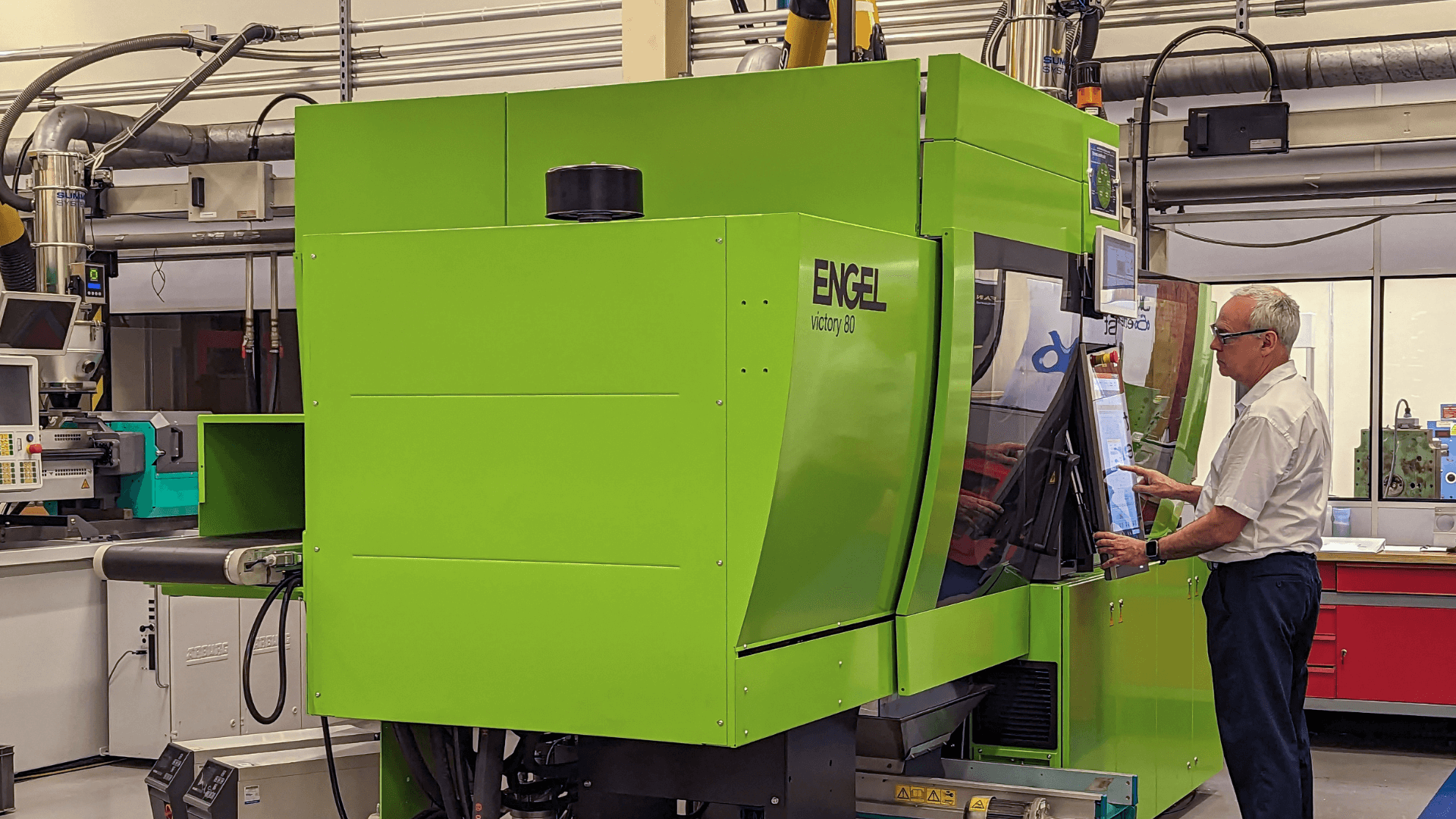

The centre is equipped with:

- Industry-standard equipment for injection moulding and blow moulding

- Lifting and ancillary equipment

- PICAT II process simulation software

The centre also offers:

- Training in operational support

- IOSH, NEBOSH and NVQ health, safety and environmental qualifications

- Polymer processing apprenticeships in lean manufacturing and science manufacturing.

Courses Available

Click on one of the categories below to discover more courses within that area.

Courses available – Operational Support

Courses available – Injection Moulding

Courses available – Blow Moulding (Extrusion)

Courses available – Extrusion (Pipe/Profile/sheet)

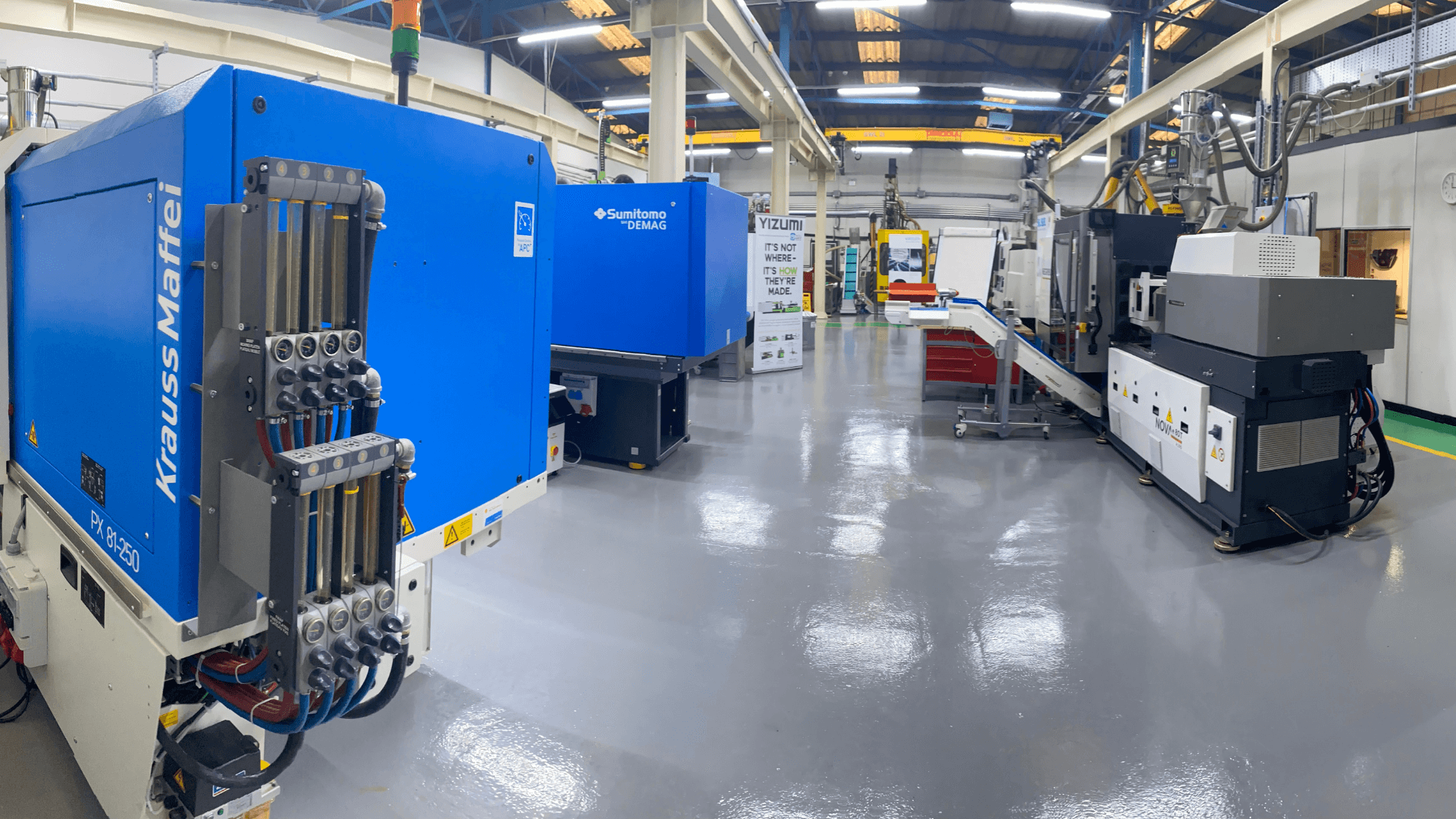

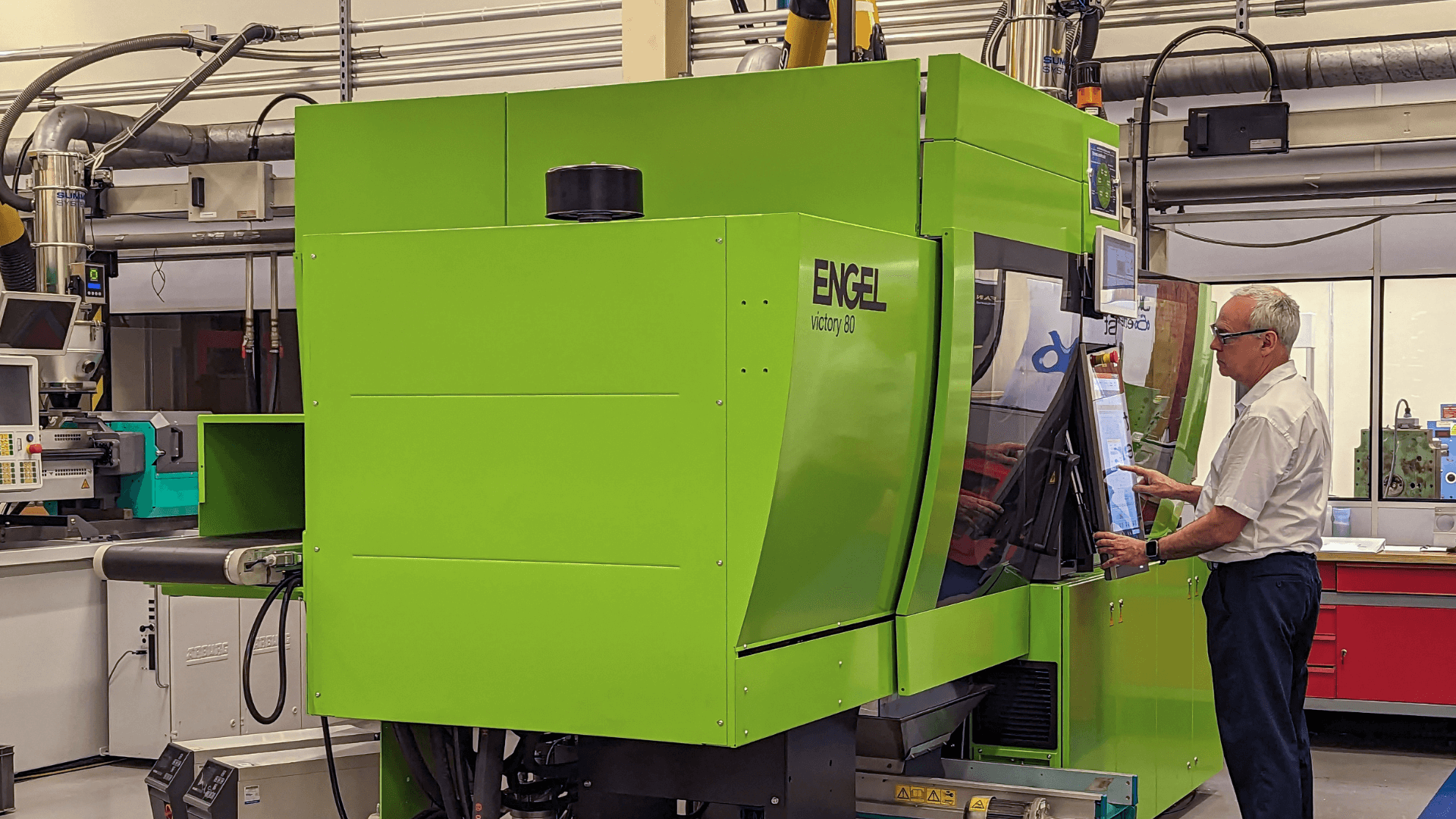

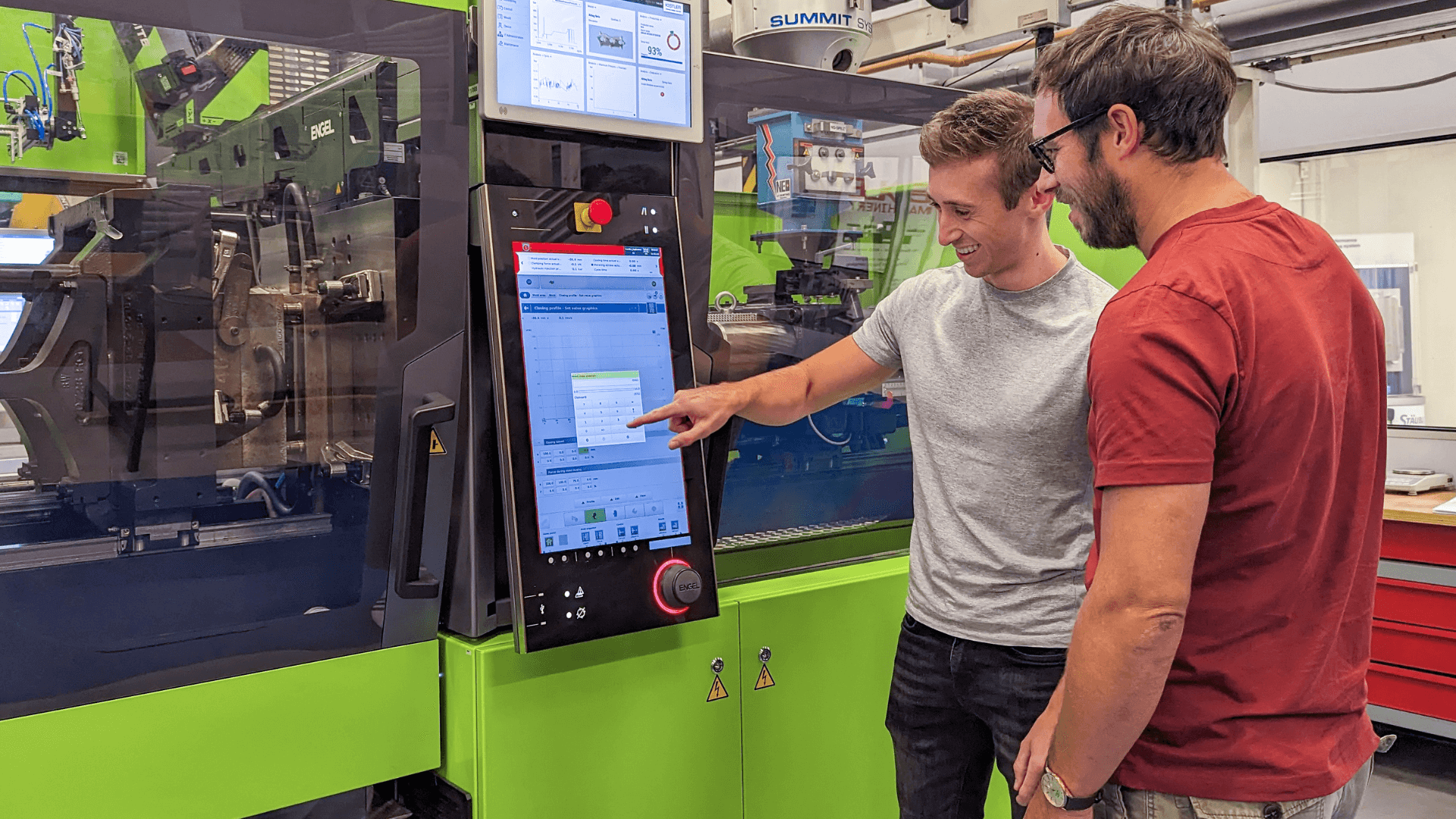

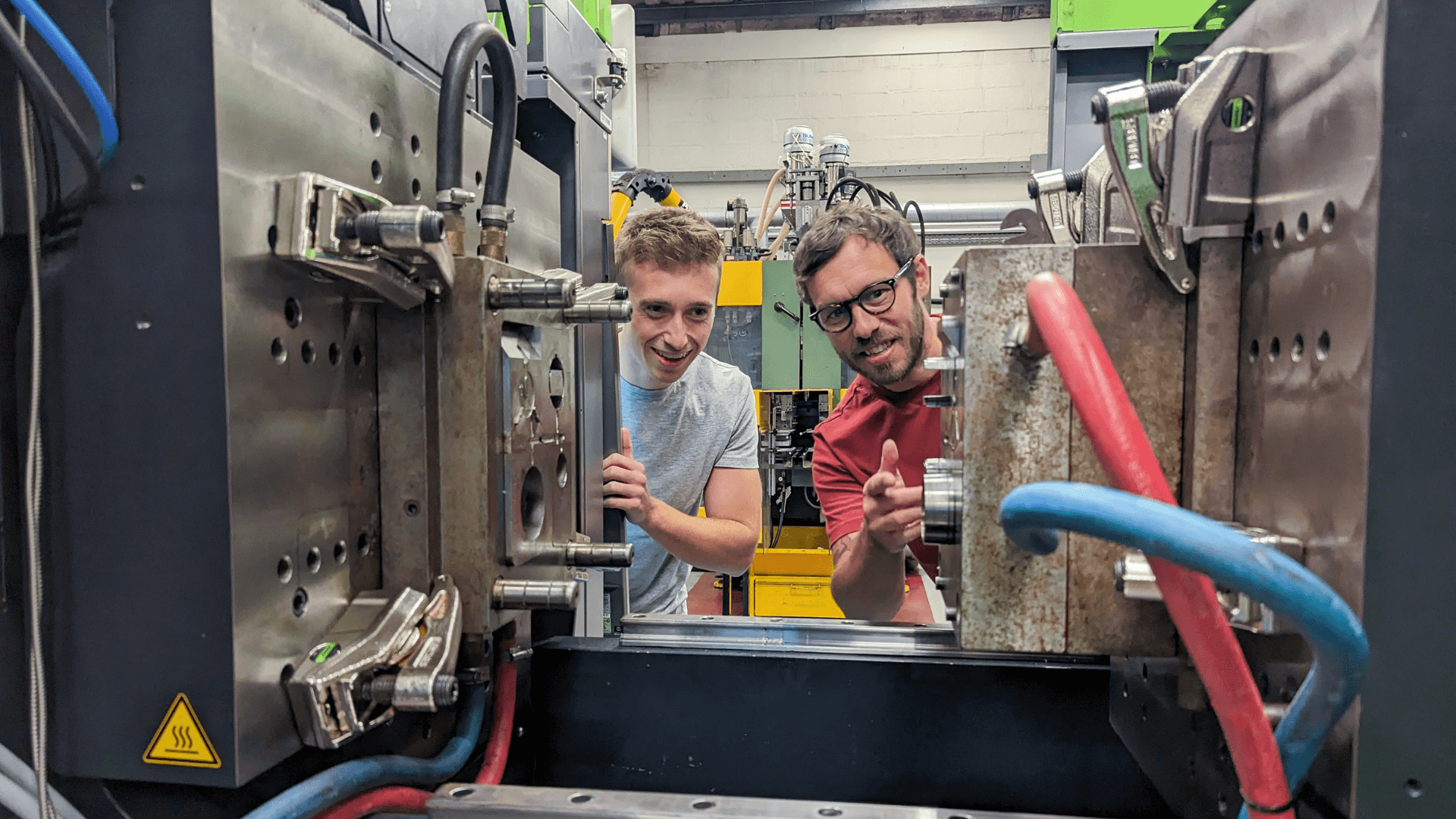

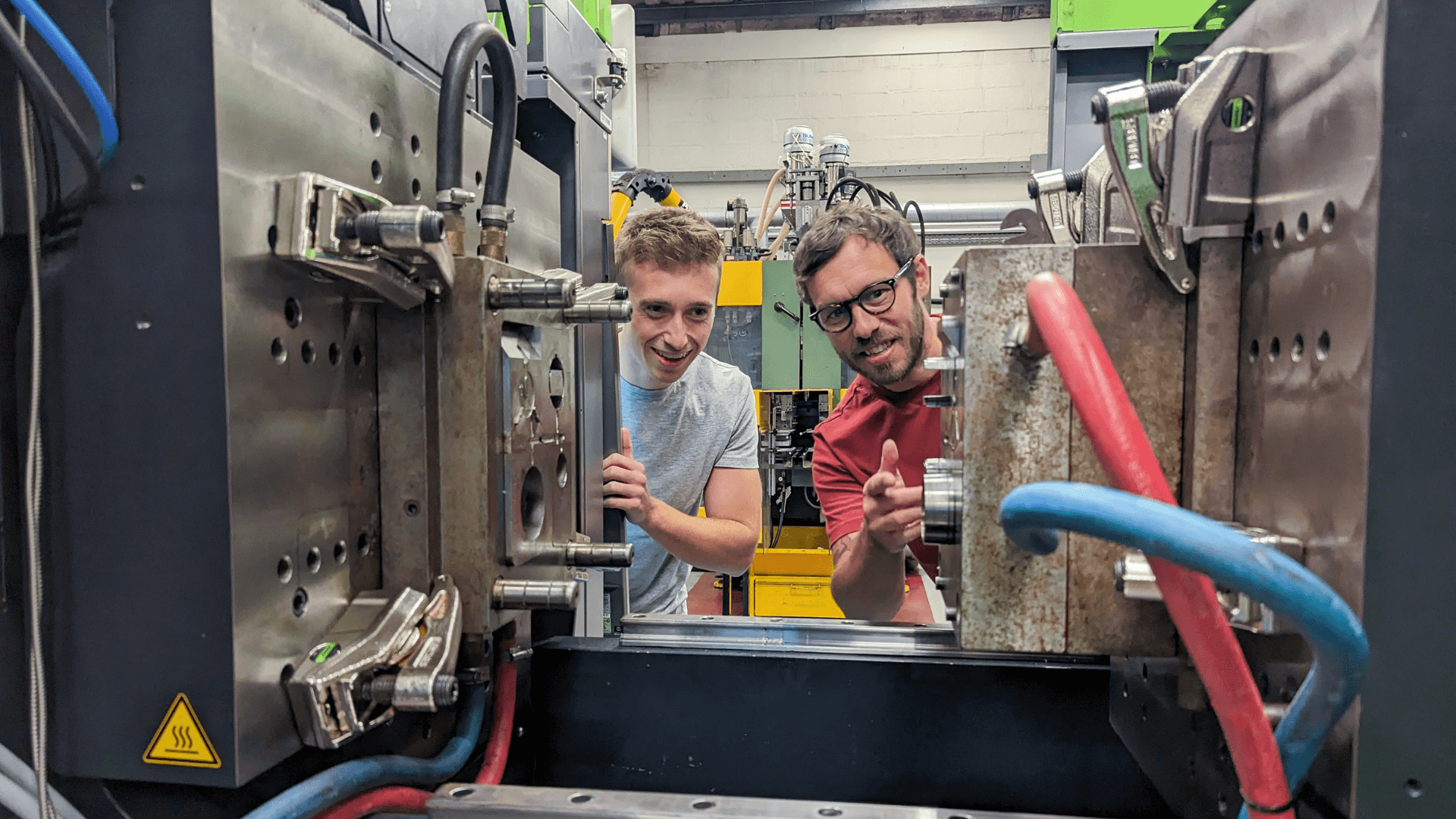

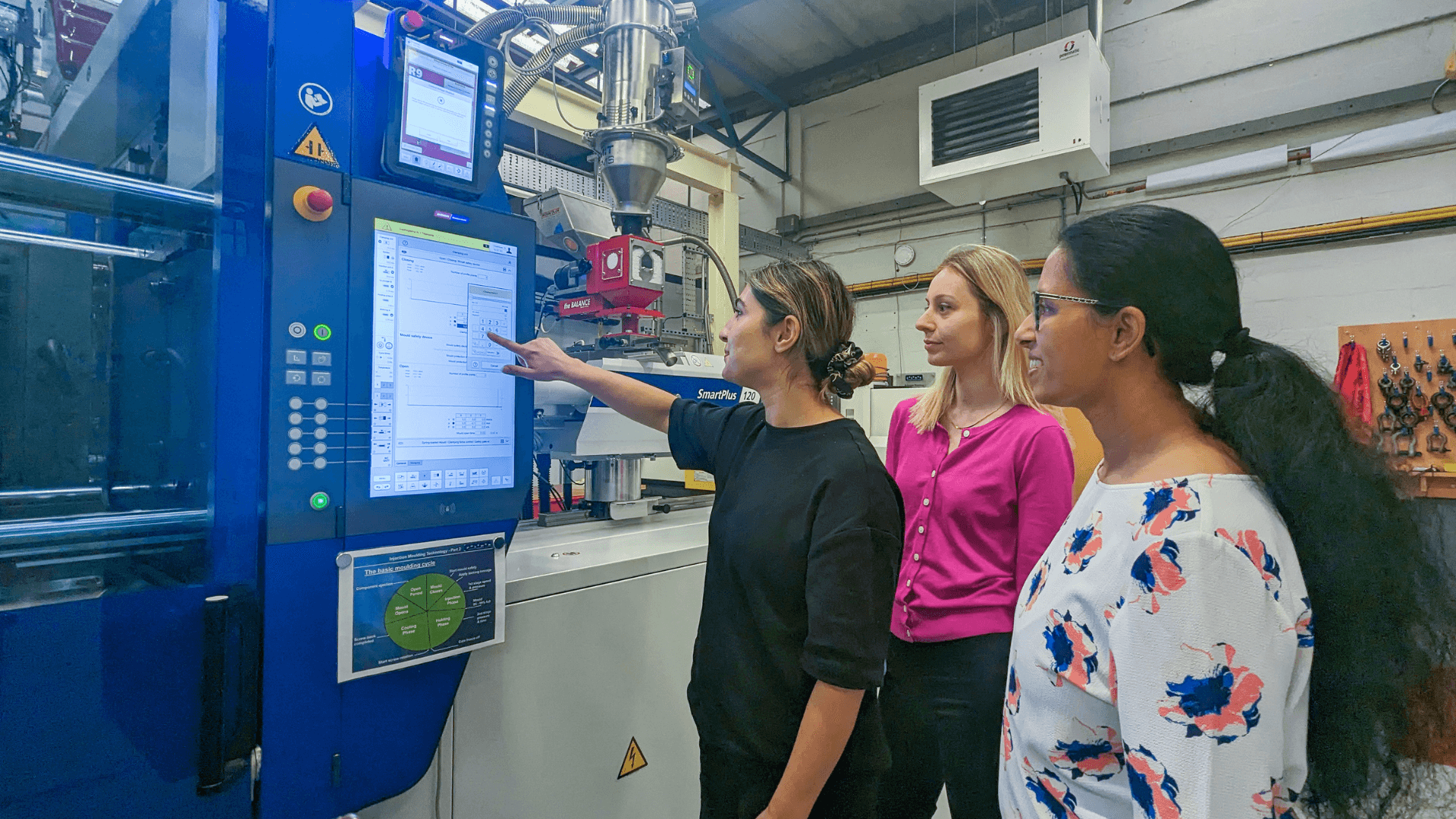

Facilities

The Polymer Training and Innovation Centre, at Stafford Park 4 in Telford, is a technical training and consultancy business owned by City of Wolverhampton College.

The centre specialises in providing injection moulding and blow moulding, and has an extensive range of industry-standard equipment.

Digital Innovation Hub

The Polymer Training Innovation Centre and the college’s digital innovation hub have teamed up to offer free consulting services to help improve your business efficiency and familiarise you with the latest developments in AI.

Technical Downloads

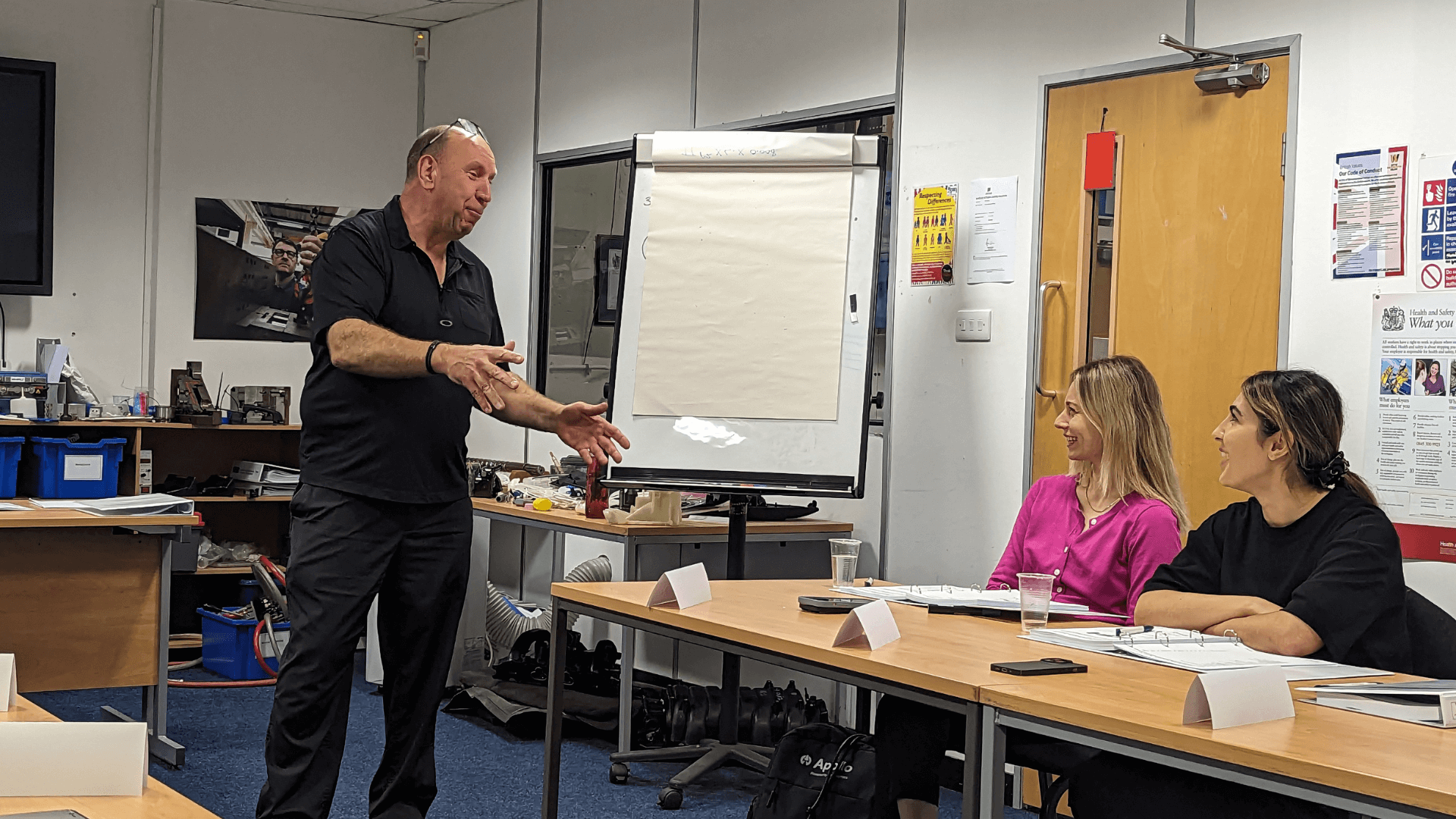

Meet the team

Steve Harratt

Steve joined the organisation under its previous name of the BPTA back in 1996 and has since then, held both training and commercial positions. His PGCE teaching qualification and MSc in Polymer Technology technical qualification supported Steve in his original role as a technical training course tutor.He has more recently headed up PTIC’s sales and marketing activities in his current role of technical sales account manager.

Ken Davies

With over 30 years’ experience, in managing health and safety in engineering / aerospace, Ken has spent the last 20 of these delivering a range of qualifications for the college.A Chartered Fellow of Institution of Occupational Safety and Health (CFIOSH), Ken’s qualifications include a degree in environmental technology, a PGCE, the NEBOSH national general certificate and a diploma in safety management.

Carrie Cottis

With a degree and over 10 years’ experience in customer service and administration in a variety of settings, Carrie is the main point of contact for all health and safety course enquiries.She works closely with the related awarding bodies to develop course materials, internal systems and examination procedures.

Darryl Starr

Darryl has 28 years of experience in the injection moulding industry and joined the college from his role as a process technician at Hoselock.He is now involved in course delivery at PTIC and draws on his experience of tool validation, automation, new equipment procurement and tool trials.Darryl is a qualified electrician and assists customers with mould trials and also provides support in a mentoring/consultancy role.

Clare Cooper

Clare is instrumental in developing PTIC’s office procedures and internal systems, as part of her customer service and sales administration role.Having been with the college for over 17 years in both administrative and quality roles, Clare’s qualifications include a degree, NVQs in customer service, business administration and a City & Guilds in quality assurance.

Andrew Dermody

Andrew has almost 40 years’ experience in engineering in both technical and managerial roles within the military, automotive and food industries and provides valuable support in the delivery of PTIC’s injection moulding and health & safety courses.He also holds a PTTLS teaching qualification and A1 assessor’s award.

Phil Suddaby

Phil has been involved in the education sector for over 12 years.He is qualified to Level 4 standard for business improvement techniques, process and IQA internal verification and quality control.Phil has also recently completed his green belt in Six Sigma to support his knowledge and skills as a lean practitioner and is currently involved in delivering the new apprenticeship standards for the lean framework.

Andrew Baker

Andrew has over 40 years’ experience in the polymer industry.He has qualifications in polymer science and experience in setting, processing, tooling, materials, and ancillaries.Although he has previously worked as a consultant/trainer in plastic injection moulding, his main focus over the last 20 years has been in the automotive sector working in NPI and production engineering for large tier 1 suppliers to JLR, Toyota, Nissan, Ford, and BMW managing projects, specifying and introducing new equipment and tooling into production, and working to budgets and deadlines.He has now returned to a training environment to pass on the skills and knowledge, gained over his time in this industry, to help the next generation who are getting involved in plastic injection moulding.

Contact us

Customer Feedback

We received the end-of-course assessment results and were very pleased with how well Adrian and Lukasz performed. They were both delighted with their achievements and found the training extremely valuable. They spoke highly of the course content, the instructor’s expertise, and the overall organisation.

The training was practical, relevant to their roles, and will certainly support their continued development. I really appreciate the effort that went into delivering the course and the clear communication throughout. We look forward to working with you again for future training needs.

Krzysztof Siwik – Blow Mould Manager for Strata Products Ltd

Thank you to the Polymer Team for all the support you have provided the lads and myself in the last couple of years, it’s been very much appreciated!

With regards to the course, I was very happy with it and since I’ve been back I’ve done a little bit of work on our moulding machines – a moulding trial of some new material, and it was good to see the principles and techniques I learned on the course being applied in real life. Our process is slightly different to straight forward moulding as we are encapsulating electrical coils, so it’s a balancing act with holding pressures and injection speeds etc but the basic principles are there. The tutors are knowledgeable and friendly, with quite an informal attitude and you get to do some hands on stuff with the machines on site. I did the IMT2 with you last year so I knew what to expect, but again, it’s a nice facility and good staff, good content and a good balance between theory and practical. Please feel free to pass on my thanks to Darren, Geoff and Bill.”

“Both myself and Darren are impressed and satisfied with results and further skillset improvement post Darren’s training at PTIC. I can see Darren coming back stronger, with much better understanding of process set-up / build up and much more knowledge than before the training. I believe Darren also feels stronger and more confident whilst processing new tooling It has also been recognised by the other members of management – for the training to give us exactly what we’ve expected in return as a business. I can’t say at this stage if other setters will be send for training as their skillset and commitment to the business is still being under the review, but I can assure you, should we decide to send resources out for training, it will be with PTIC.

I found the general awareness and detailed discussions on specific issues related to plant with ideas for improvements the most interesting. This was the most informative course I have been on for years and I found all content relevant. Good course; allows a better understanding of the extrusion system. Good course – will help in my job. This course was a very welcome introduction to a very important topic for me – I look forward to the next installment. I will plan to include my Design Engineers in future. The whole course was interesting to build up the picture; the processing details were the most interesting though. A good insight to polymer life and how degradation occurs. All aspects of the course were interesting – technical / process. The theory day of the Mould Mounting course was informative and helped expand on what I knew already from practical tasks at work. The course also helped to explain how the injection moulding machine carries out the various tasks – not just why. This helped me to understand the operation of the machine.

All of the course was interesting because it all relates to my job role and it’s good to know what all the different things on the machine are all called.

Apprenticeship Success Stories

Mark Walvin

Course: Polymer Processing Technician Apprenticeship Level 3

Mark Walvin

Course: Polymer Processing Technician Apprenticeship Level 3

Paul Smith

Course: Polymer Processing Technician Apprenticeship Level 3

Paul Smith

Course: Polymer Processing Technician Apprenticeship Level 3

Martin Dean

Course: Polymer Processing Technician Apprenticeship Level 3 (ST1328)

Martin Dean

Course: Polymer Processing Technician Apprenticeship Level 3 (ST1328)

Joshua Vinters

Course: Apprenticeship Science and Manufacture Engineering Level 3 at Polymer Training & Innovation Centre.

Joshua Vinters

Course: Apprenticeship Science and Manufacture Engineering Level 3 at Polymer Training & Innovation Centre.

Iohani Annan

Course: Polymer Processing Technician Apprenticeship Level 3

Iohani Annan

Course: Polymer Processing Technician Apprenticeship Level 3

Bayley Morley

Course: Polymer Processing Technician Apprenticeship Level 3

Bayley Morley

Course: Polymer Processing Technician Apprenticeship Level 3

Alex Jones

Course: Polymer Processing Technician Apprenticeship Level 3